1.Warranty time: 1 year

2.Delivery time: 3-5 days

3.Product quality: new or discontinued second-hand

1. We are a global trading company, we have a large stock of spare parts, we also produce energy storage batteries

2. Our main sales products are industrial automation control equipment accessories, such as: controller board, processor module, communication module, input and output module, power module (various circuit boards and cards), touch screen, servo driver, servo motor, sensor, cable......

3. We can not only provide new products, but also supply cold and discontinued spare parts, all the discontinued parts will go through strict testing to ensure the reliability of product performance, so that customers can buy and use at ease

4. For more information, please contact us: Contact: Amy | Email: saul01@qq.com | Tel(WhatsApp/Wechat): +86-15359298283

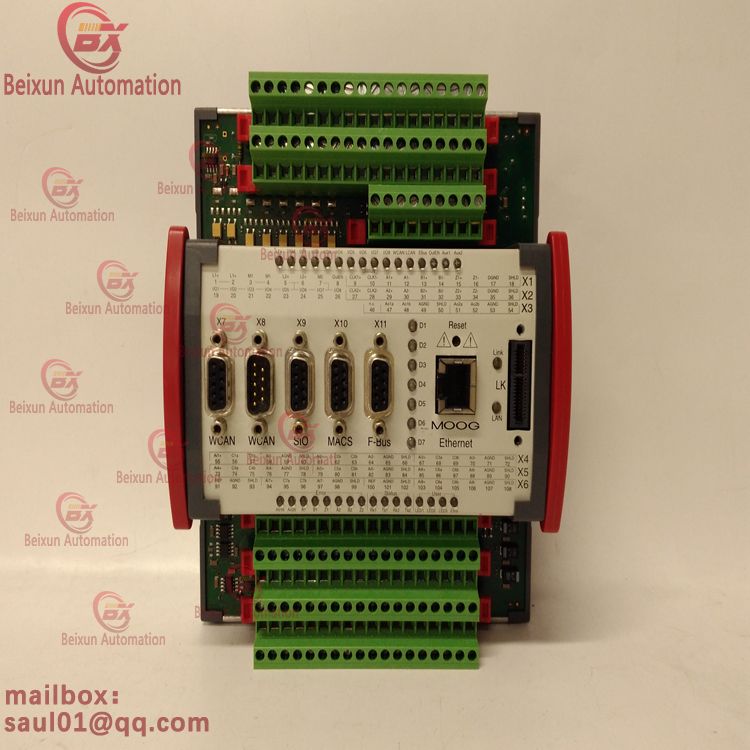

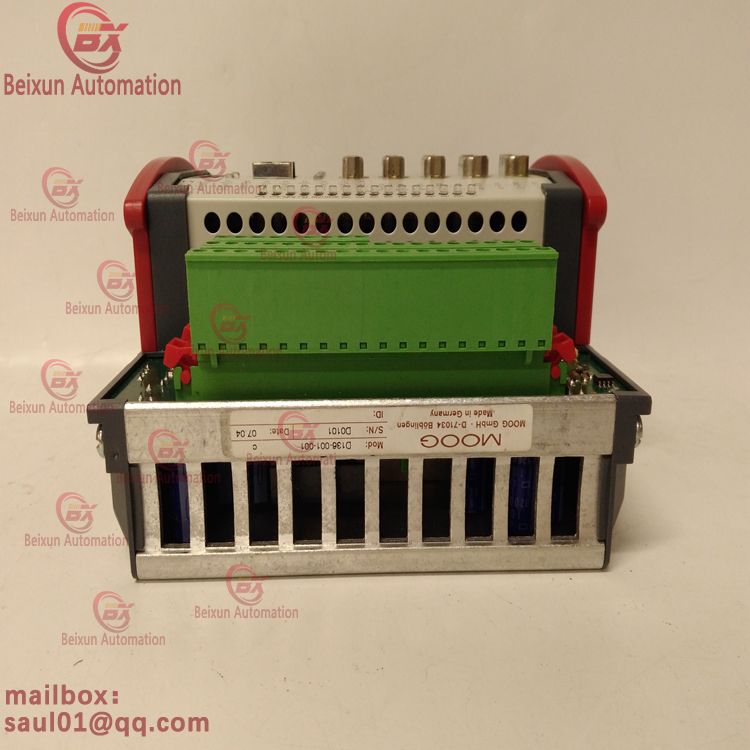

MOOG CPU Controller D136-001-007 D138-002-002 D136-001-008a

MOOG CPU Controller D136-001-007 D138-002-002 D136-001-008a

MOOG CPU Controller D136-001-007 D138-002-002 D136-001-008a

4 Hardware Anti-jamming measures

4.1 Suppression of power interference

The plc system power supply must be separated from the power supply of the entire power supply system, and the shielded isolation transformer is generally added between entering the plc system. A twisted pair of not less than 2mm2 must be used between the secondary side of the shielded isolation transformer and the plc system. The shield is generally located between the two coils on the first and secondary sides and is connected to the ground, so that the direct coupling between the coils can be eliminated. In addition, when the harmonics of the power supply are more serious, a filter can be added in front of the isolated regulator to eliminate most of the harmonics of the power supply. If necessary, a low-pass filter can be connected to the power supply line to filter out high-frequency interference signals. The filter should be placed before the isolation transformer, that is, filter first and then isolate. Separating the power supply system by separating the power supply of controllers, i/o channels and other devices with their own isolation transformers also helps to combat grid interference.

4.2 Suppression of interline interference

The plc control system line has a power line, input/output line, power line and ground line, improper wiring will cause electromagnetic induction and electrostatic induction and other interference, so it must be wired in accordance with specific requirements, such as equal spacing as far as possible, and avoid the line winding.

(1) Ground cable

For safety and suppression of interference, the system is generally properly grounded. The system grounding methods generally include floating ground, direct ground and capacitive ground. For plc control system, it is a high-speed low-level control device, should use direct grounding mode. Due to the influence of the signal cable distribution capacitance and the input device filter, the signal exchange frequency between the devices is generally lower than 1mhz, so the grounding wire of the plc control system uses one-point grounding and one-point grounding in series. The centrally arranged plc system is suitable for parallel one-point grounding, and the central ground point of each device is led to the grounding pole by a separate grounding wire. If the distance between the devices is large, the series one-point grounding method should be used. Use a large section copper bus bar (or insulated cable) to connect the cabinet center ground point of each device, and then connect the ground bus directly to the ground pole. Use a copper conductor with a cross section greater than 20mm2 for the ground cable, and a copper bar with a cross section greater than 60mm2 for the main bus bar. The grounding resistance of the grounding pole is less than 2ω, the grounding pole is best buried 10 ~ 15m away from the building, and the plc system grounding point must be more than 10m away from the ground point of the strong current equipment. When the signal source is grounded, the shielding layer should be grounded on the signal side. When not grounded, should be grounded on the plc side; When there is a joint in the middle of the signal line, the shielding layer should be firmly connected and insulated, and multi-point grounding must be avoided. When the shielded twisted pair of multiple measuring points signals is connected with the multi-core twisted total screen cable, the shielding layers should be connected to each other and treated with insulation. Select the appropriate connection to the single point contact. plc power line, i/o power line, input and output signal lines, AC lines, DC lines should be routed separately as far as possible. The switching signal line and the analog signal line should also be routed separately, and the latter should use a shielded line, and the shielding layer should be grounded. Digital transmission lines should also use shielded lines, and the shielding layer should be grounded. The plc system is best grounded separately, and can also be publicly grounded with other equipment, but it is strictly prohibited to be grounded in series with other equipment. When connecting the ground cable, note the following:

8200-226 - WOODWARD - SERVO POSITION CONTROLLER W/MARINE LISTING

84402052 - WOODWARD - CONTROL

5466-355 - WOODWARD - MODULE, REMOTE TRANSCEIVER INTERFACE

8561904 - WOODWARD - GOVERNOR

8273-1012 - WOODWARD - 2301E, 24VDC INPUT, HAZARDOUS LOCATION,

5463-785 - WOODWARD - INPUT MODULE ANALOG 420 8POINT

5463-879 - WOODWARD - INPUT MODULE THERMOCOUPLE TYPE ALL 8POINT

84401934 - WOODWARD - CONTROL

9907-004 - WOODWARD - MASTER SYNCHRONIZER/LOAD CONTROL

84401579 - WOODWARD - MODULE

8440-1878 - WOODWARD - SYNCHRONIZER AND LOAD CONTROL DIGITAL

5456-676 - WOODWARD - TRANCEIVER MODULE

9907-1290 - WOODWARD - CONTROL PROACTII W/HIGH OUTPUT SENSOR CIRCUIT

84401925 - WOODWARD - MODULE

8272387 - WOODWARD - POWER SENSOR

8406-120 - WOODWARD - GENERATOR CONTROL 4INPUT 150-300VAC 40-70HZ EGCP-2

99071289 - WOODWARD - CONTROL

84401614 - WOODWARD - GENSET CONTROL PACKAGE 230/400VAC 5AMP

GCP-3245B/BPQ - WOODWARD - GENSET CONTROL PACKAGE 230/400VAC 5AMP

84402049 - WOODWARD - CONTROL

8440-2050 - WOODWARD - OPERATOR INTERFACE EASY GEN 3000 4-1/2X3-1/2IN

8251057 - WOODWARD - ACTUATOR

8405-073 - WOODWARD - ACTUATOR PROACTII CCW MS CONNECT SPEED CONTROL

D8250501 - WOODWARD - ACTUATOR

A8516038 - WOODWARD - PART

8271468 - WOODWARD - SPEED CONTROL

8516042 - WOODWARD - GOVERNOR

8440-1930 - WOODWARD - CONTROL MODULE

9905384 - WOODWARD - CONTROL

8272-702 - WOODWARD - SENSOR MODULE POWER REAL

2301E - WOODWARD - DIGITAL LOAD SHARING AND SPEED CONTROL 602-1450

8250749 - WOODWARD - ACTUATOR

8406-121 - WOODWARD - CONTROL SMALL-MEDIUM DIESEL GENERATOR SET EGCP-2

9901018 - WOODWARD - CONTROL

9905973 - WOODWARD - MODULE

8402776 - WOODWARD - VALVE

D8250349 - WOODWARD - ACTUATOR

E8250502 - WOODWARD - ACTUATOR

8731011 - WOODWARD - SPEED CONTROL

82731011 - WOODWARD - SPEED MODULE

9907-018 - WOODWARD - 2301A-LOAD SHARING SPEED CONTROL 2301A 20-40VDC

9907-005 - WOODWARD - MASTER SYNCHRONIZER AND LOAD CONTROL MODULE

MOOG CPU Controller D136-001-007 D138-002-002 D136-001-008a