1.Warranty time: 1 year

2.Delivery time: 3-5 days

3.Product quality: new or discontinued second-hand

1. We are a global trading company, we have a large stock of spare parts, we also produce energy storage batteries

2. Our main sales products are industrial automation control equipment accessories, such as: controller board, processor module, communication module, input and output module, power module (various circuit boards and cards), touch screen, servo driver, servo motor, sensor, cable......

3. We can not only provide new products, but also supply cold and discontinued spare parts, all the discontinued parts will go through strict testing to ensure the reliability of product performance, so that customers can buy and use at ease

4. For more information, please contact us: Contact: Amy | Email: saul01@qq.com | Tel(WhatsApp/Wechat): +86-15359298283

Controller redundancy module/Controller communication interface module)

1. Core positioning and functions

Redundant control core:

This module is a key redundant component of Ovation DCS controllers, such as Ovation Controller Model 3, to achieve dual-machine Redundancy at the controller level.

Seamless primary and backup switching:

The data and status of the primary and standby controllers are synchronized in real time. When the primary controller fails, it automatically switches to the standby controller at the millisecond level to ensure zero interruption of process control.

High-speed data synchronization:

Key information such as I/O data, logic state, real-time clock and so on are synchronized between master and standby controllers through dedicated optical fibers or cables.

2. Role in the Ovation system architecture

Installation location:

It is directly inserted into the dedicated redundant slot of the Ovation controller substrate (such as 1C31197G01, 1C31197G02) and works with the CPU module (such as 1C31224G01).

System level reliability:

It constitutes a high availability Controller Pair, which is the core hardware of the power plant/plant to realize the "no single point of failure" control architecture.

Network integration:

Some versions may integrate the Ovation high-speed control network interface (such as OvationNet) to support real-time communication between the controller and the operation station and the history station.

3. Key features and technical highlights

Dual channel redundant bus:

Using two independent communication channels (such as Channel A/B), the failure of any channel does not affect the switching function.

Fault self-diagnosis:

Real-time monitoring of the status of the primary and secondary controllers, synchronous link quality, trigger alarm and record event (SOE) in case of failure.

Bumpless Transfer:

The switching process keeps the output signal stable and avoids process perturbations.

Hot swap design:

Support online module replacement, maintenance without downtime.

LED status indicator:

The module panel provides multi-color leds to visually display key information such as power supply, primary/standby status, synchronization status, and communication links.

4. Typical application scenarios

Power Industry:

Thermal power plant boiler control (BMS/CCS), steam turbine speed control (DEH), hydropower station monitoring.

Process Industry:

Petroleum refining, chemical process control (such as reactor, distillation tower), natural gas treatment.

Critical Infrastructure:

Nuclear power non-safety control, large water treatment plant, metallurgical automation.

5. Technical parameters (typical)

Description of project parameters

Compatible with the Ovation Controller Model 3 series

Redundant communication medium multimode fiber or coaxial cable

Synchronization speed microsecond level data synchronization

Switching time ≤ 50ms (usually < 10ms)

Operating temperature 0°C ~ 60°C (industrial grade)

The power input is provided by the controller substrate at +5VDC

Certification standard CE, UL, IEC 61131, etc

Step 6: Importance

System availability guarantee:

The redundancy design can significantly improve the MTBF (mean time to failure) of the controller and meet the requirements of continuous production.

Safety and Compliance:

Compliance with industrial safety standards such as IEC 61508 SIL2 reduces the risk of loss of control.

Maintenance cost optimization:

Support online maintenance and reduce the loss of unplanned downtime.

7. Precautions for use

Match consistency:

The hardware/firmware versions of the redundant controller pairs must be exactly the same, otherwise the synchronization may fail.

Fiber maintenance:

The optical fiber interface should be dustproof and bending proof, and the link light failure should be checked regularly.

Electrostatic protection:

It is necessary to wear an anti-static wristband during operation, and the module is stored in an anti-static bag.

Configuration synchronization:

The Ovation Developer Studio tool is used to verify the redundant configuration after replacing the module.

8. Compatibility and alternative models

Directly compatible substrate:

1C31197G01, 1C31197G02 (Ovation Controller base plate)

Related modules:

CPU module: 1C31224G01, 1C31203G01

Power module: 1C31262G01

I/O communication module: 1C31166G01

Replacement/upgrade Model:

Please refer to the official Emerson documentation (such as 1C31179G03 May be a later version), and the old system may need to be upgraded to the new Controller (such as Ovation Compact Controller).

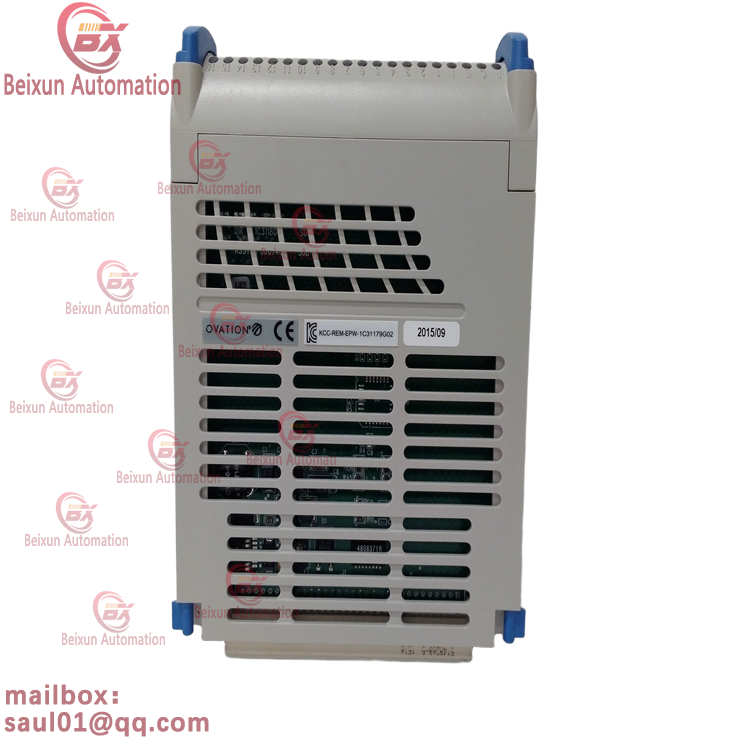

Emerson 1C31179G02 DCS System Module

Emerson 1C31179G02 DCS System Module

Emerson 1C31179G02 DCS System Module

Emerson 1C31179G02 DCS System Module

You can also learn about these:

Emerson FLOBOSS S600 Flow Computer Process management controller

Emerson KL2001X1-BA1 KL2001X1-BB1 KL3001X1-BA1 control module

Emerson Emerson A6500-UM Universal measurement card