1.Warranty time: 1 year

2.Delivery time: 3-5 days

3.Product quality: new or discontinued second-hand

1. We are a global trading company, we have a large stock of spare parts, we also produce energy storage batteries

2. Our main sales products are industrial automation control equipment accessories, such as: controller board, processor module, communication module, input and output module, power module (various circuit boards and cards), touch screen, servo driver, servo motor, sensor, cable......

3. We can not only provide new products, but also supply cold and discontinued spare parts, all the discontinued parts will go through strict testing to ensure the reliability of product performance, so that customers can buy and use at ease

4. For more information, please contact us: Contact: Amy | Email: saul01@qq.com | Tel(WhatsApp/Wechat): +86-15359298283

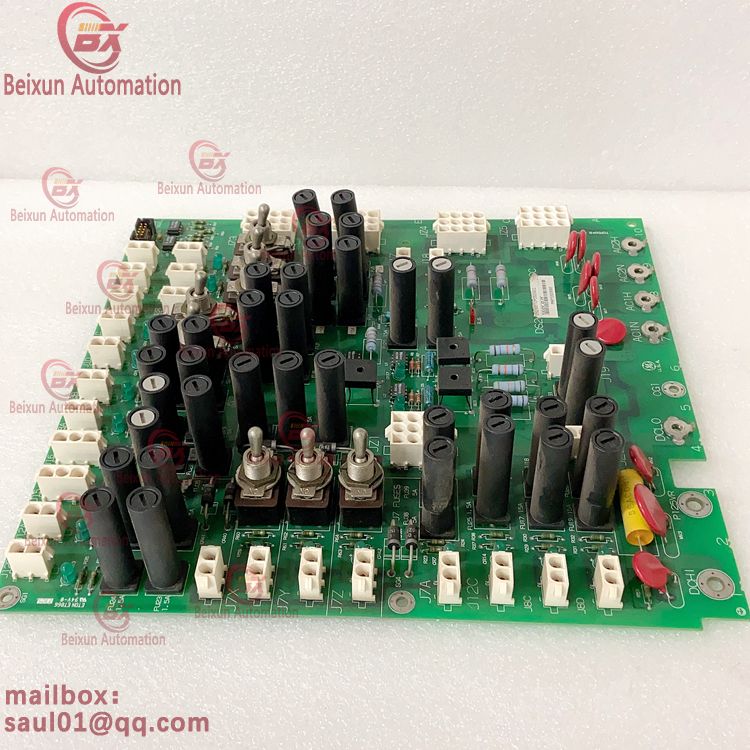

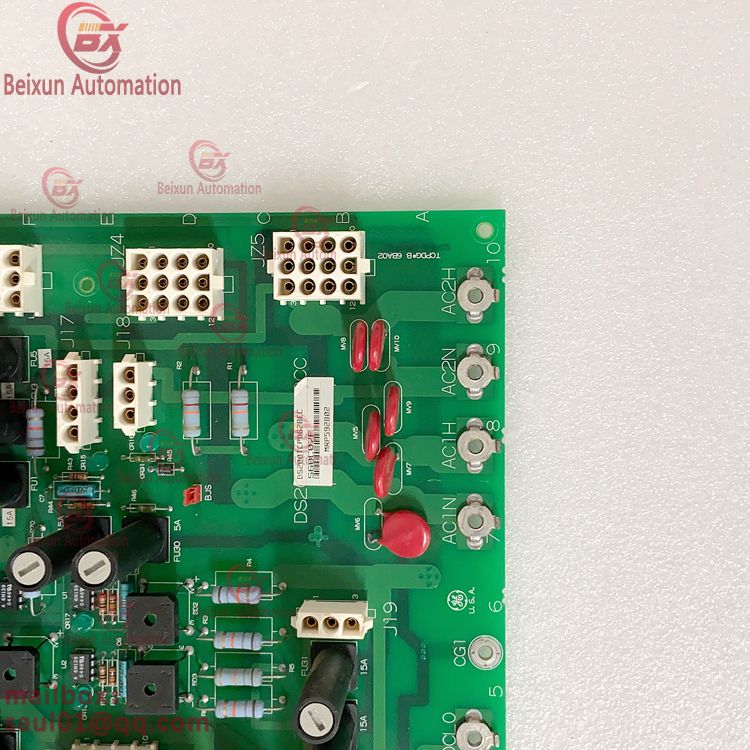

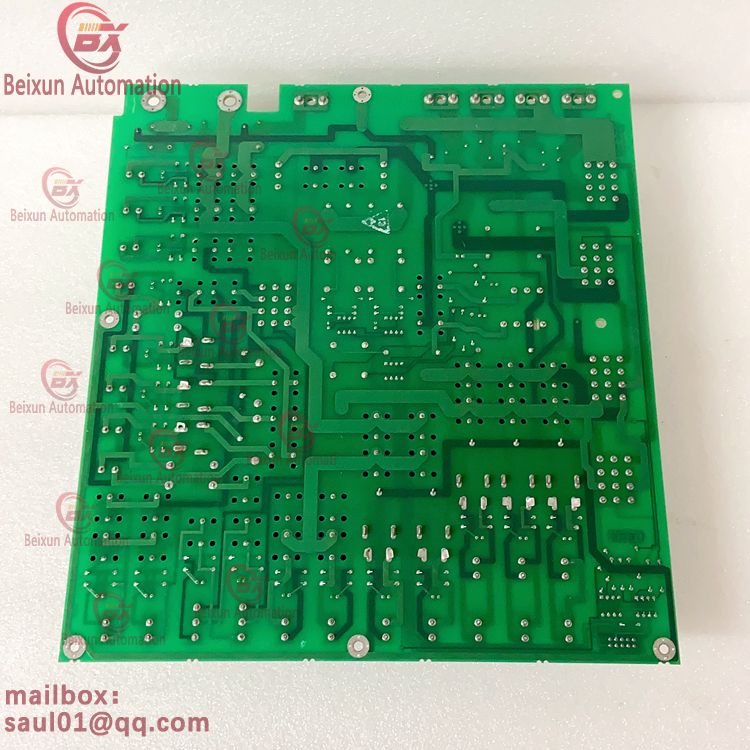

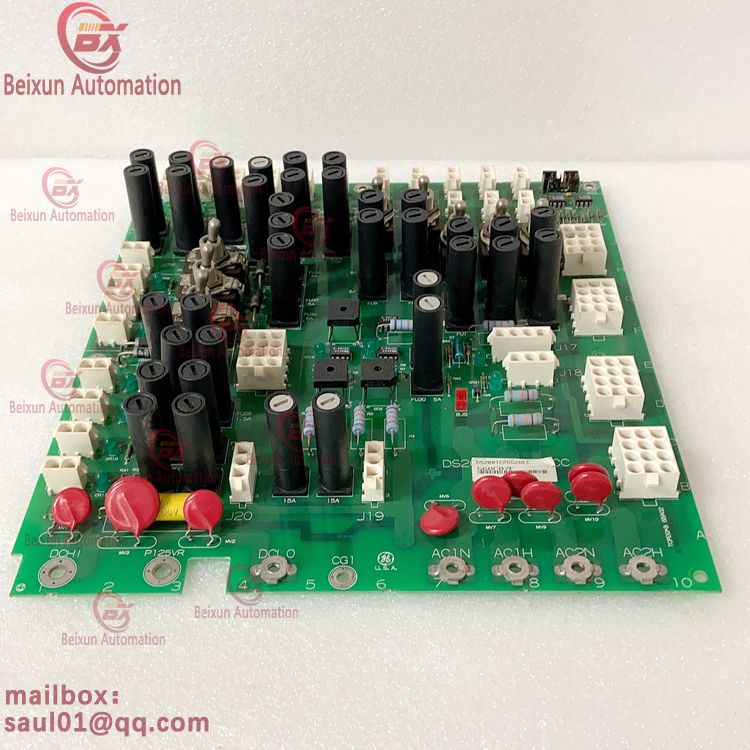

GE DS200DCFBG1BNC Turbine control power board

When using the single-ended method, the total voltage input of the amplifier consists of the signal voltage plus the common mode voltage. The difference method applies a common mode voltage to both inputs. These are cancelled out (due to the differential nature of the inputs); Thus, only the signal voltage is "seen".

Battery powered instruments:

Switching DC:

When switching coils, a back electromotive force is usually generated on the coil when the contact is disconnected. This can damage the contacts, and it can also introduce nasty transients to the system and cause spikes in some instrument signals

Placing a flywheel diode on the coil can easily reduce this, thus providing an easy path for the dissipation of the back electromotive force energy.

Switching alternating current (AC) :

A similar situation applies when switching coils but using AC. In this case, a suppression RC network with 0.1 microfarads and 100 ohm resistance can solve the problem.

What is OPC UA?

OPC UA stands for OPC Unified Architecture. It is a platform-independent, scalable standard that allows for the secure exchange of information in industrial systems. The Open Platform Communications (OPC) Foundation oversees and maintains interoperability standards, protocols, and specifications for data exchange, primarily for industrial automation operations, and published OPC UA in 2008.

OPC UA is supported by Windows, macOS, Android, and Linux. It can also be used for embedded and bare metal systems that lack an operating system. OPC UA is compatible with PCS, cloud infrastructure, PLCS, microcontrollers, and cyber-physical systems (CPS).

By providing a platform for industrial organizations to integrate heterogeneous technologies, OPC UA aims to improve interoperability between hardware devices and enterprise planning and automation applications.

Where is OPC UA used?

OPC UA is used in industrial systems such as oil and gas, agriculture, healthcare and pharmaceuticals, vital services such as power grids and wastewater treatment plants, and Internet of Things (IoT) systems such as smart city applications.

Equipment diagnostics, asset management, production management, quality control, data acquisition, enterprise reporting, data security, data integration for GUI interfaces, remote worker support, and event monitoring are all common uses of OPC UA.

Monitoring the uptime of security cameras, alerting faulty sensors, controlling office temperatures, remotely managing automated machinery, forecasting workloads, connecting embedded devices, and assisting remote employees are some real-world examples.

OPC UA is also compatible with the Industrial Internet of Things (IIoT). For example, OPC UA can be used to transfer data from embedded devices, such as temperature sensors, to the cloud to monitor consumption and device efficiency.

Using objects to access data in OPC UA allows the system to retrieve small amounts of context-specific information for remote workers as needed for a particular job. Alternatively, objects can be searched to examine all data of the entire plant operation, such as when developing graphical user interfaces for ERP systems, resource allocation programs, and accounting systems.

OPC UA facilitates vertical data transfer between heterogeneous drives and advanced applications where synchronization is required between devices in remote locations and resource planning and plant control systems.

The OPC UA standard improves industrial safety applications. In the event of a cyberattack on a field device, the OPC UA Incident Management Protocol may automatically shut down the plant and isolate the affected network or enable limited access to the designated network, enabling business continuity while the incident is investigated.

How does OPC UA work?

model

OPC UA provides basic standards for exposing data to any application or device that wants to use model usage data. OPC UA is a data model that focuses on information. It consists of a generic object model with an extensible type system and a built-in data access model. These built-in models define functions such as alarm and event information, historical data information, data access details, device descriptions, and program execution.

Data can also be accessed through custom models called adjoint models. These are used in a variety of industries, including the manufacture of injection molding machines and robotics engineering.

Connectivity and data flow

OPC UA supports communication between components in industrial organizations at five levels: Enterprise, Management, Operations, Control, and field (vendor-specific equipment).

Devices disclose their data through OPC UA, which allows this information to be transmitted over the network to consuming applications via ordinary Web services. Data is transmitted over IP-based protocols and SOAP, and the low-end server uses UA TCP. Non-opc UA clients can request data from OPC UA servers over HTTP using normal SOAP Web services.

The OPC UA wrapper, bridge, and gateway software allows data to be transferred between OPC UA levels on vendor-specific hardware. The OPC UA wrapper is especially useful when migrating from OPC Classic to OPC UA, or when OPC servers support UA but OPC clients do not.

Service Based Architecture (SOA)

The SOA client-server communication framework is the foundation of OPC UA. OPC UA consists of OPC UA server and OPC UA client.

OPC UA servers connect OPC UA clients to applications and control systems such as MES and SCADA, and securely access industrial automation data through the use of OPC UA information models that define how data is organized, stored, and collected. The name of the OPC UA server refers to the OPC UA software standard of the machine, not the hardware, which can be a virtual server.

A client that can support the OPC UA information model is called an OPC UA client. OPC UA clients use OPC UA servers to get data from and write data to system components.

SOA systems, such as OPC UA, connect devices on multiple network nodes and integrate various applications over the network.

node

Nodes are the basic data units in the OPC UA address space that provide a consistent mechanism for OPC UA servers to represent objects to OPC UA clients. A node is a bit of information (for example, a unique temperature) that includes properties, actual data values, and one or more references to other nodes, each in its own address space. Therefore, a single temperature will occupy multiple addresses in the address space.

A node is identified by a unique node ID, which includes a namespace URI (unique resource identifier), a data type, and the identifier itself. Each node is associated with a different namespace. On the OPC UA server, the namespace URI is stored in a separate namespace table. Namespace tables store different URIs for the information model used by each enterprise, each with its own set of rules to indicate how data should look and behave. This allows OPC UA to extend its services without modifying the standard base design.

Nodes in OPC UA contain a number of classes that allow variants to be built on top of the base node. Objects (physical entities), methods (functions that hold data when queried), and variables belong to the eight main node types in OPC UA (actual data).

In OPC UA, object node classes are essential for creating complex data and distinguishing between comparable but different entities, such as temperature sensors for air conditioners and those for boilers.

Advantages and disadvantages of ODC UA

Advantages of ODC UA

Self-service: - Since no scripting is required, operations teams can easily connect to any OPC UA server. They can also use device auto-discovery to fully automate device identification and integration with Cumulocity IoT.

Support for common device types: - Each device only needs to be defined once. The device type specification specifies the mapping from the computer to the associated IoT asset and the configuration, such as which data to synchronize at what frequency.

Configuration in the Cloud: - Through cloud-based remote configuration, we offer the OPC UA iot gateway to be installed by a field engineer with zero touch. So engineers can connect to a variety of devices wherever they are, without having to be in the same room.

Drawbacks of ODC UA

Device-specific constraints: - Some proprietary software vendors have noted device-specific constraints, such as the limitations that exist between OPC UA servers and the iFIX and HMI/SCADA components used in GE's software automation products. Specific features such as electronic signatures, enhanced failover, and historical data sources are among the limitations.

Complex configuration: - In practice, OPC UA often manages the exchange of data between MES and SCADA information systems, as well as between low-level devices. It is ideal for system monitoring and reporting. Although it is designed to manage interoperability between different devices, it has been criticized for being inflexible in handling different data structures from different vendors and for being difficult to install.

GE DS200DCFBG1BNC Turbine control power board

GE DS200DCFBG1BNC Turbine control power board

GE DS200DCFBG1BNC Turbine control power board

GE DS200DCFBG1BNC Turbine control power board

GE DS200DCFBG1BNC Turbine control power board

MAIN PRODUCT :

ABB: Industrial robot spare parts DSQC series, Bailey INFI 90, IGCT, etc., for example: 5SHY6545L0001 AC10272001R0101 5SXE10-0181,5SHY3545L0009,5SHY3545L0010 3BHB013088R0001 3BHE009681R0101 GVC750BE101, PM866, PM861K01, PM864, PM510V16, PPD512 a10-15000 3BHE040375R1023, PPD113, PP836A, PP865A, PP877, PP881, PP885,etc.,

GE: spare parts such as modules, cards, and drivers. For example: VMIVME-7807, VMIVME-7750, WES532-111, UR6UH, SR469-P5-HI-A20, IS230SRTDH2A, IS220PPDAH1B, IS215UCVEH2A , IC698CPE010,IS200SRTDH2ACB,etc.,

Bently Nevada: 3500/3300/1900 system, Proximitor probe, etc.,for example: 3500/22M,3500/32, 3500/15, 3500/20,3500/42M,1900/27,etc.,

Invensys Foxboro: I/A series of systems, FBM sequence control, ladder logic control, incident recall processing, DAC, input/output signal processing, data communication and processing, such as FCP270 and FCP280,P0904HA,E69F-TI2-S,FBM230/P0926GU,FEM100/P0973CA,etc.,

Invensys Triconex: power module,CPU Module,communication module,Input output module,such as 3008,3009,3009X,3720,3721,4351B,3805E,8312,3511,4355X,etc.,