1.Warranty time: 1 year

2.Delivery time: 3-5 days

3.Product quality: new or discontinued second-hand

1. We are a global trading company, we have a large stock of spare parts, we also produce energy storage batteries

2. Our main sales products are industrial automation control equipment accessories, such as: controller board, processor module, communication module, input and output module, power module (various circuit boards and cards), touch screen, servo driver, servo motor, sensor, cable......

3. We can not only provide new products, but also supply cold and discontinued spare parts, all the discontinued parts will go through strict testing to ensure the reliability of product performance, so that customers can buy and use at ease

4. For more information, please contact us: Contact: Amy | Email: saul01@qq.com | Tel(WhatsApp/Wechat): +86-15359298283

PCD232A 3BHE022293R0101 two-phase driver is a highly reliable driver with independent intellectual property rights of MOTEC (China), suitable for driving two-phase stepper motors. It has the characteristics of small size, high power density, rich functions and so on, and has a very high performance-price ratio compared with similar foreign products.

The specific parameters are as follows:

1. Input voltage: 18~60VDC (DC power supply);

2. Output current: maximum 6A (peak);

3.DC+/DC- is a DC power supply input with a voltage range of 18 to 60VDC.

4.A+/A- and B+/B- connect the two windings of the two-phase stepper motor and exchange any pair of cables to change the running direction of the motor;

5.P+/ P- is a pulse signal, 5V interface, if connected to other voltage signals, please refer to the interface circuit diagram;

6.D+/D- is the direction signal, 5V interface, if connected to other voltage signals, please refer to the interface circuit diagram;

7.F+/F- is a release signal, 5V interface, the user can control the signal during operation, so that the stepper motor into the release state.

The servo drive has torque control, speed control and position control modes, and can switch modes online. Permanent magnet synchronous electricity can be realized

The machine's high-speed weak magnetic control, asynchronous motor high-speed spindle drive; Support a variety of PG expansion cards, such as incremental ABZUVW encoder, Resolver encoder

And sine-cosine encoders, etc. For the servo spindle of the machine tool, it can realize the spindle quasi-stop, spindle tool change, rigid tapping, spindle swing, and other functions.

Can achieve rotary shear function, Angle synchronization.

Digital closed loop driver, using a new generation of 32-bit DSP control technology and power Angle control technology.

The maximum speed can reach 3000rpm or more, and the high-speed torque attenuation is much lower than that of ordinary open-loop drivers.

It can greatly improve the high-speed performance and torque utilization rate of the stepper motor.

Effectively reduce the heat and vibration of the motor, thereby improving the processing efficiency and accuracy of the machine.

The current control technology based on load can effectively reduce the heat of the motor and prolong the service life of the motor.

The driver's built-in position and alarm output signals are convenient for the host computer to monitor and control.

The out-of-position alarm function ensures the safe operation of the processing equipment.

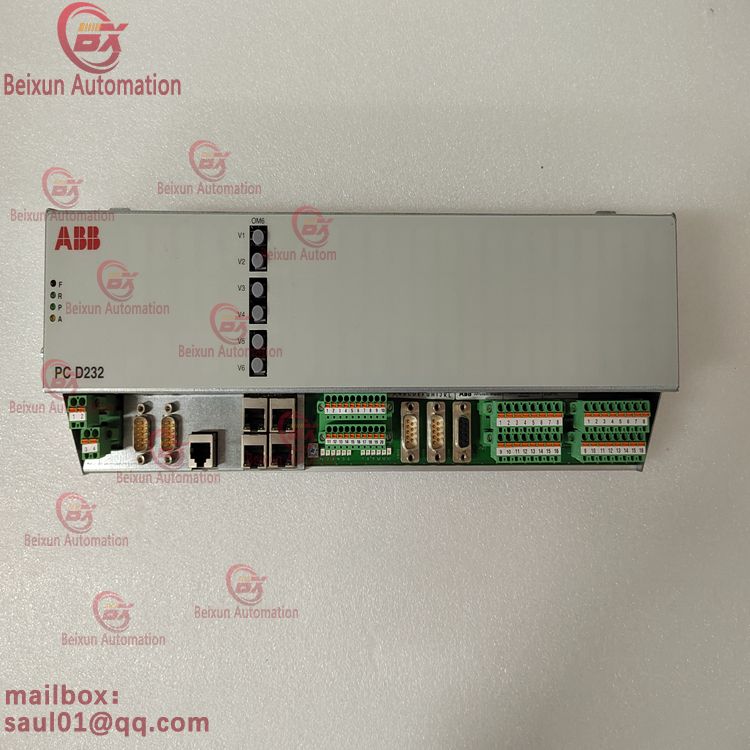

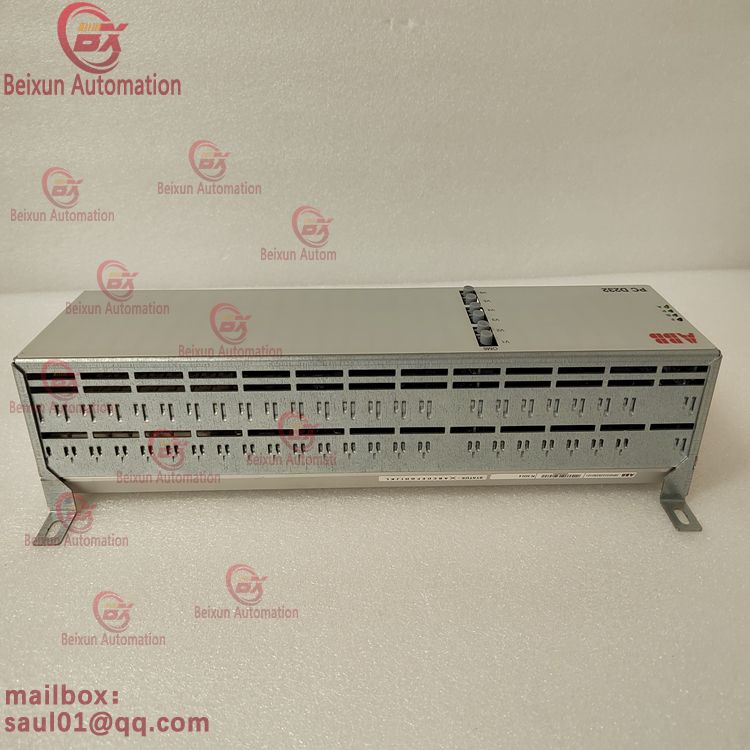

ABB PCD232A3BHE022293R0101 excitation module

ABB PCD232A3BHE022293R0101 excitation module

ABB PCD232A3BHE022293R0101 excitation module

ABB PCD232A3BHE022293R0101 excitation module

ABB PCD232A3BHE022293R0101 excitation module