1.Warranty time: 1 year

2.Delivery time: 3-5 days

3.Product quality: new or discontinued second-hand

1. We are a global trading company, we have a large stock of spare parts, we also produce energy storage batteries

2. Our main sales products are industrial automation control equipment accessories, such as: controller board, processor module, communication module, input and output module, power module (various circuit boards and cards), touch screen, servo driver, servo motor, sensor, cable......

3. We can not only provide new products, but also supply cold and discontinued spare parts, all the discontinued parts will go through strict testing to ensure the reliability of product performance, so that customers can buy and use at ease

4. For more information, please contact us: Contact: Amy | Email: saul01@qq.com | Tel(WhatsApp/Wechat): +86-15359298283

Product details

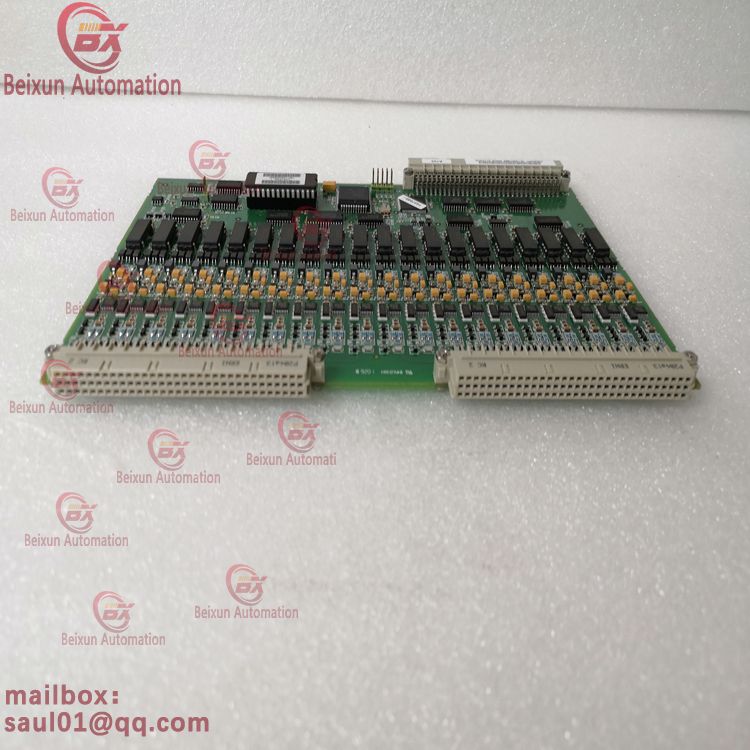

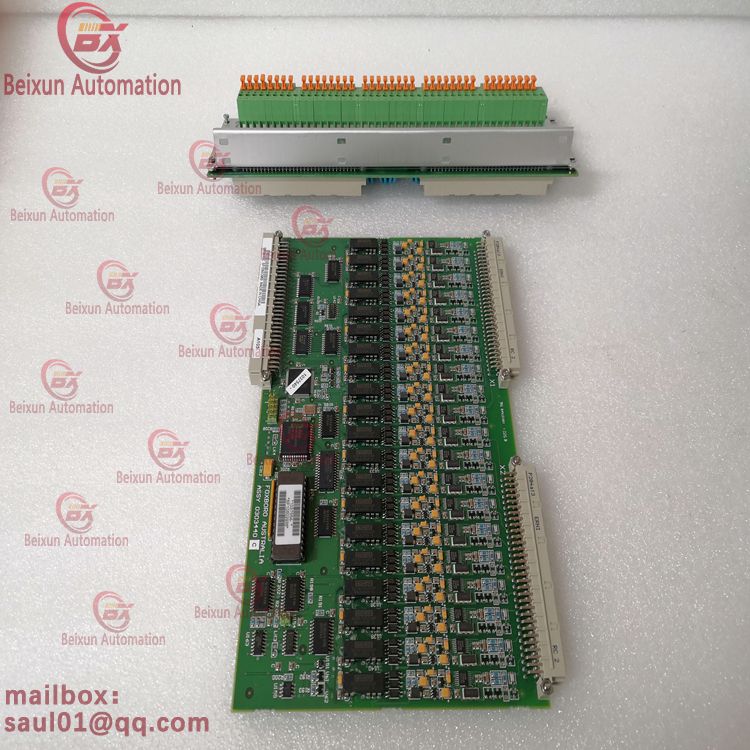

FOXBORO 0399071D 0303440C+0303443B Analog input module DEH speed up process adopts main valve (TV) control, when the speed up to 2950r/min, switch the valve, main

The valve control is switched to high voltage regulator (GV) control, and the rear speed is 3000 r/min.

Conventional valve switching is often due to the TV and GV opening and closing rates do not match well, resulting in large fluctuations in turbine speed [1], to this end, through the improvement of valve switching control scheme: valve switching starts

When, the coefficient of opening the high adjustment gate gradually changes from 1 to 0, and the speed PID acts on TV and GV at the same time, that is:

GV valve position output = open high [] coefficient x100+(1- open high valve coefficient)x valve position given (speed PID output)

TV valve position output =(1- open high valve coefficient)x100+ open high [J coefficient x valve position given (speed PID output)

After the new valve switching control scheme is adopted, the turbine speed is very stable in the process of valve [] switching in DEH during each start of the unit, and the speed fluctuation does not exceed 5r/min, which is satisfied

DEH turbine speed control requirements.

LVDT dual channel highly selected position feedback mode, if two LVDTS are broken at the same time, the oil motor will be fully open, so it does not meet the safety design principles of the servo system. Therefore, the original LVDT line break detection is judged

After disconnection, pull down the DC voltage after LVDT demodulation, and then pull up LVDT DC voltage. The original LVDT DC voltage high selection circuit is changed to a low selection circuit, so that if a single LVDT breaks the line, the

LVDT DC voltage is greater than the valve position command voltage, due to the use of low selection circuit, will not affect the normal operation of the servo system. If both LVDTS are disconnected, the LVDT DC voltage is greater than the valve position instruction

Voltage, oil motor will be completely off. This modification satisfies both safety and redundancy design principles.

FOXBORO 0399071D 0303440C+0303443B Power module

FOXBORO 0399071D 0303440C+0303443B Power module

FOXBORO 0399071D 0303440C+0303443B Power module

FOXBORO 0399071D 0303440C+0303443B Power module

FOXBORO 0399071D 0303440C+0303443B Power module