1.Warranty time: 1 year

2.Delivery time: 3-5 days

3.Product quality: new or discontinued second-hand

1. We are a global trading company, we have a large stock of spare parts, we also produce energy storage batteries

2. Our main sales products are industrial automation control equipment accessories, such as: controller board, processor module, communication module, input and output module, power module (various circuit boards and cards), touch screen, servo driver, servo motor, sensor, cable......

3. We can not only provide new products, but also supply cold and discontinued spare parts, all the discontinued parts will go through strict testing to ensure the reliability of product performance, so that customers can buy and use at ease

4. For more information, please contact us: Contact: Amy | Email: saul01@qq.com | Tel(WhatsApp/Wechat): +86-15359298283

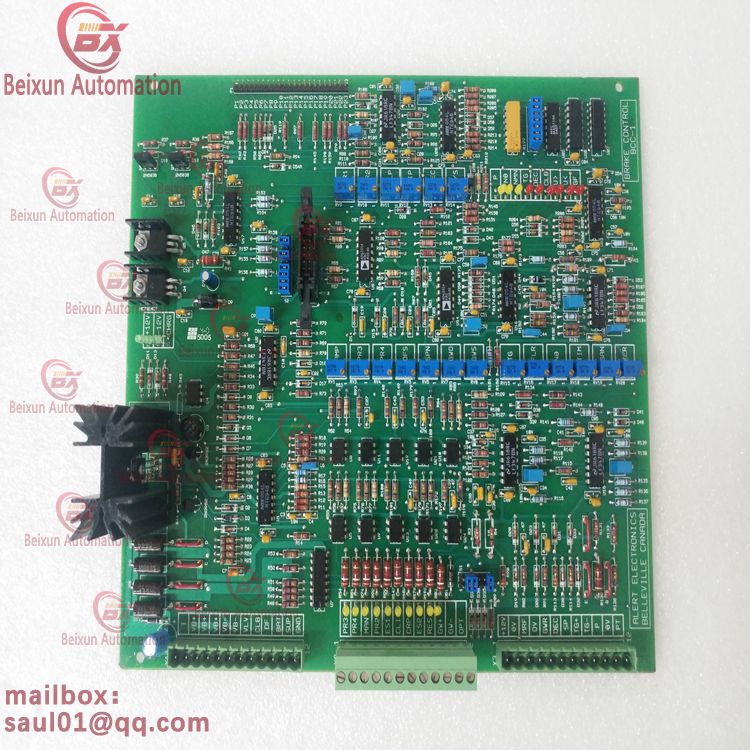

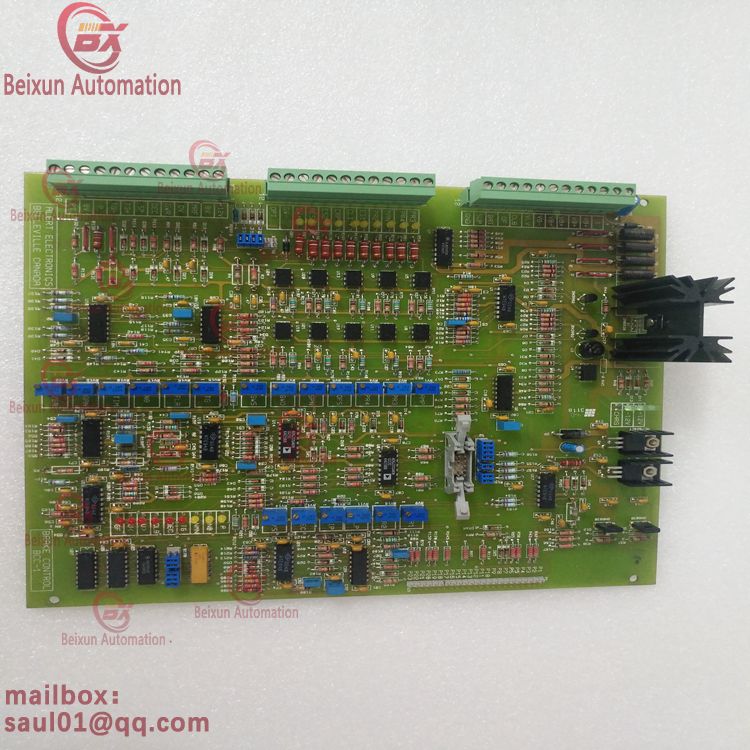

The ABB Gate-controlled BCC-1 Brake Control panel is a brake control device specifically designed for mine lifting applications. The following is a detailed analysis of its functions and features:

Main functions:

Proportional control function: This function is mainly used for general manual brake operations, such as lifting after unloading, towing braking, and braking applications during general stops.

Emergency braking control function: This function is designed to maintain deceleration during lifting, independent of existing braking conditions (such as payload, direction, coefficient of friction, etc.). This feature is particularly important in friction-lifting applications, where the constant braking torque of emergency braking control can lead to skidding conditions.

Detection function:

The brake control panel BCC-1 also has a number of enhanced control detection functions, including tachometer generator monitoring, DC power supply monitoring and system pressure indication. These features provide comprehensive monitoring of the status of the upgrade system.

Operation characteristics:

Signal standardization: Through the standardization of signals, the test and operation of the brake control board BCC-1 is relatively easy.

Leds and test points: These design elements further simplify the commissioning and troubleshooting process.

Working principle (based on ABB gate control system) :

Manual mode: Control according to the wishes of the driver and the release and brake command of the elevator.

Automatic mode: The gate control command issued by the elevator is directly controlled to release and apply the gate sequence.

Constant deceleration brake control: In the emergency stop, through the hoist and the safety loop relay of the brake control system, the brake control board BCC-1 and the speed measuring machine and other equipment jointly control, to achieve constant deceleration brake.

Technical specifications (part) :

Hydraulic control: When the lifting machine releases the brake command, the hydraulic station control valve and the proportional control valve will get electricity, so that the system oil pressure rises, and then control the opening and closing of the disc brake.

Oil pressure regulation: By controlling the power gain and power loss of different valves, the system oil pressure can be adjusted in different ranges to meet the different operating states of the hoist.

Application field:

It is mainly used in mine lifting applications, but it is also suitable for other industrial areas where high precision brake control is required.

In summary, ABB gate-controlled BCC-1 brake control board is a powerful and easy to operate brake control equipment, it ensures the safe and stable operation of the lifting system through accurate proportional control and emergency brake control functions.

ABB gated BCC-1 brake control panel

ABB gated BCC-1 brake control panel

ABB gated BCC-1 brake control panel

ABB gated BCC-1 brake control panel

ABB gated BCC-1 brake control panel