1.Warranty time: 1 year

2.Delivery time: 3-5 days

3.Product quality: new or discontinued second-hand

1. We are a global trading company, we have a large stock of spare parts, we also produce energy storage batteries

2. Our main sales products are industrial automation control equipment accessories, such as: controller board, processor module, communication module, input and output module, power module (various circuit boards and cards), touch screen, servo driver, servo motor, sensor, cable......

3. We can not only provide new products, but also supply cold and discontinued spare parts, all the discontinued parts will go through strict testing to ensure the reliability of product performance, so that customers can buy and use at ease

4. For more information, please contact us: Contact: Amy | Email: saul01@qq.com | Tel(WhatsApp/Wechat): +86-15359298283

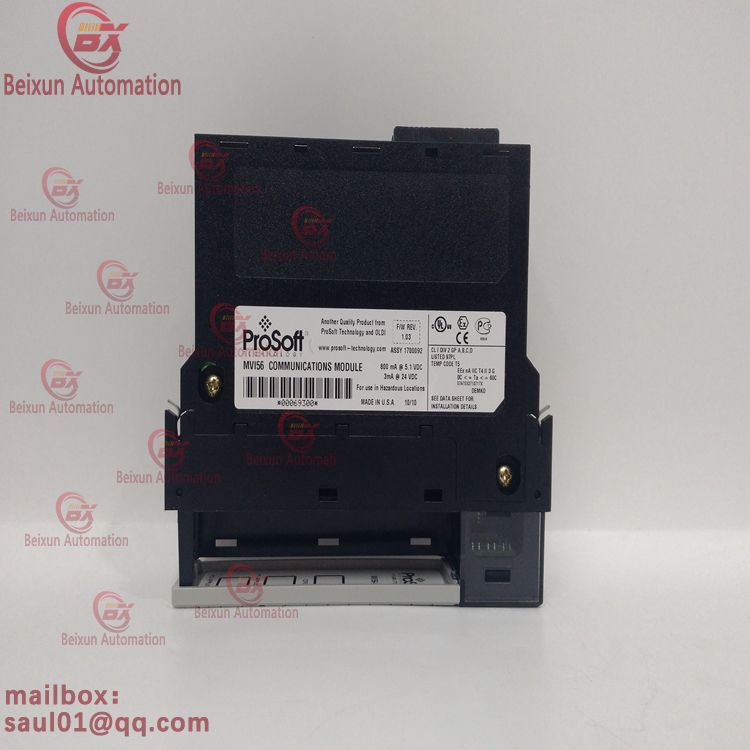

PROSOFT Communication Interface module MVI56-LTQ is a communication solution specifically designed for industrial automation and control systems. Here are the details and features of the module:

Product Overview:

The PROSOFT MVI56-LTQ communication interface module is designed for the ControlLogix PLC platform and allows users to integrate the ControlLogix system with Lotus Notes databases.

This module enables the industrial automation system to collect, process and distribute data through Lotus Notes, and improves the overall communication capability and data management efficiency of the system.

Key features and benefits:

Lotus Notes Integration: Allows the ControlLogix system to communicate bidirectionally with the Lotus Notes database for reading and writing data.

Enhanced data processing capabilities: Provides powerful data processing and format conversion functions to support complex database queries and data operations.

Modular design: Easy to install and configure, reducing integration and maintenance complexity.

Compatibility: Fully compatible with Allen-Bradley ControlLogix systems, ensuring seamless integration with existing PLC systems.

Advanced diagnostic functions: Built-in diagnostic and status monitoring functions help users quickly identify and solve communication problems and improve system reliability.

Application field:

Manufacturing: For the collection and management of production data, to achieve real-time monitoring and optimization of the production process.

Energy management: Used in power generation and distribution systems for data acquisition and analysis to optimize energy use and management.

Oil and gas: For the collection and analysis of critical data during oil and gas extraction and refining to ensure efficient and safe production processes.

Chemical: In chemical production, it is used for data monitoring and control of reactors and other critical equipment to improve production efficiency and product quality.

Enterprise Resource Planning (ERP) integration: acts as a bridge between enterprise resource planning systems and production floor data, enabling seamless flow and integration of information.

Operation and maintenance recommendations:

Regular inspection and testing: Regular functional testing and inspection of the module to ensure its communication capability and data processing performance.

Environmental condition monitoring: Ensure that the working environment of the module meets the requirements of temperature, humidity, and electromagnetic compatibility to prevent environmental factors from affecting the device.

Diagnosis and troubleshooting: Use the built-in diagnostic tools of the module to regularly check the status of the system and identify and resolve potential problems in a timely manner.

Additional information:

The module also supports a variety of communication protocols, and can communicate with different manufacturers and different models of equipment and systems to achieve data sharing and control instruction transmission.

In terms of price, depending on the supplier and the quantity purchased, the price can range from hundreds to thousands of yuan.

In summary, the PROSOFT Communication interface module MVI56-LTQ is a powerful, easy to use and maintain communication solution for a variety of industrial automation and control system application needs.

PROSOFT communication interface module MVI56-LTQ

PROSOFT communication interface module MVI56-LTQ

PROSOFT communication interface module MVI56-LTQ

PROSOFT communication interface module MVI56-LTQ

PROSOFT communication interface module MVI56-LTQ