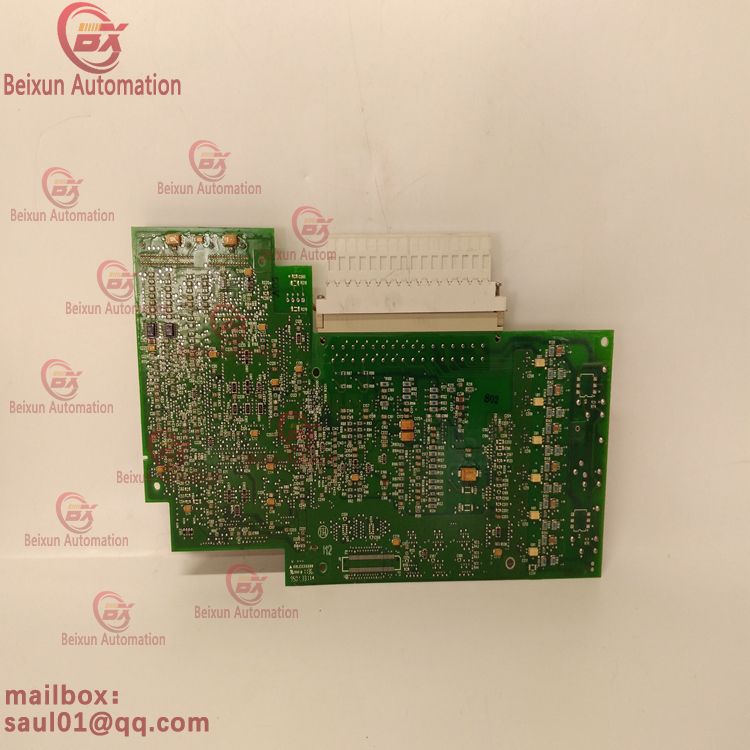

1.Warranty time: 1 year

2.Delivery time: 3-5 days

3.Product quality: new or discontinued second-hand

1. We are a global trading company, we have a large stock of spare parts, we also produce energy storage batteries

2. Our main sales products are industrial automation control equipment accessories, such as: controller board, processor module, communication module, input and output module, power module (various circuit boards and cards), touch screen, servo driver, servo motor, sensor, cable......

3. We can not only provide new products, but also supply cold and discontinued spare parts, all the discontinued parts will go through strict testing to ensure the reliability of product performance, so that customers can buy and use at ease

4. For more information, please contact us: Contact: Amy | Email: saul01@qq.com | Tel(WhatsApp/Wechat): +86-15359298283

06/28/2021

Below is a listing of the faults and alarms (with descriptions) for the ABB ACH550 series of VFDs, along with suggested corrective action to eliminate the fault or alarm condition.

At the bottom of this page there is a link to the diagnostics section of the user manual for the ABB ACH550 drive that gives further information for troubleshooting, if needed.

Fault Listing

1 OVERCURRENT

Output current is excessive. Check for and correct:

• Excessive motor load.

• Insufficient acceleration time (parameters 2202 ACCELER TIME 1 and 2205 ACCELER TIME 2).

• Faulty motor, motor cables or connections.

-----

2 DC OVERVOLT

Intermediate circuit DC voltage is excessive. Check for and correct:

• Static or transient overvoltages in the input power supply.

• Insufficient deceleration time (parameters 2203 DECELER TIME 1 and 2206 DECELER TIME 2).

• Verify that overvoltage controller is ON (using parameter 2005).

-----

3 DEV OVERTEMP

Drive heatsink is overheated. Temperature is at or above limit.

R1…R4 & R7/R8: 115 °C (239 °F)

R5/R6: 125 °C (257 °F)

Check for and correct:

• Fan failure.

• Obstructions in the air flow.

• Dirt or dust coating on the heat sink.

• Excessive ambient temperature.

• Excessive motor load.

-----

4 SHORT CIRC

Fault current. Check for and correct:

• A short-circuit in the motor cable(s) or motor.

• Supply disturbances.

ACH550-UH User’s Manual 1-283

Diagnostics

-----

5 RESERVED

Not used.

-----

6 DC UNDERVOLT

Intermediate circuit DC voltage is not sufficient. Check for and correct:

• Missing phase in the input power supply.

• Blown fuse.

• Undervoltage on mains.

-----

7 AI1 LOSS

Analog input 1 loss. Analog input value is less than AI1FLT LIMIT (3021).

Check for and correct:

• Source and connection for analog input.

• Parameter settings for AI1FLT LIMIT (3021) and 3001 AI<MIN FUNCTION.

-----

8 AI2 LOSS

Analog input 2 loss. Analog input value is less than AI2FLT LIMIT (3022).

Check for and correct:

• Source and connection for analog input.

• Parameter settings for AI2FLT LIMIT (3022) and 3001 AI<MIN FUNCTION.

-----

9 MOT TEMP

Motor is too hot, based on either the drive’s estimate or on temperature

feedback.

• Check for overloaded motor.

• Adjust the parameters used for the estimate (3005…3009).

• Check the temperature sensors and Group 35 parameters.

-----

10 PANEL LOSS

Panel communication is lost and either:

• Drive is in local control mode (the control panel displays HAND or OFF),

or

• Drive is in remote control mode (AUTO) and is parameterized to accept start/stop, direction or reference from the control panel.

To correct check:

• Communication lines and connections

• Parameter 3002 PANEL COMM ERROR.

• Parameters in Group 10: START/STOP/DIR and Group 11:

REFERENCE SELECT (if drive operation is AUTO).

-----

11 ID RUN FAIL

The motor ID run was not completed successfully. Check for and correct:

• Motor connections

• Motor parameters 9905…9909

-----

12 MOTOR STALL

Motor or process stall. Motor is operating in the stall region. Check for and correct:

• Excessive load.

• Insufficient motor power.

• Parameters 3010…3012.

-----

14 EXTERNAL FLT 1

Digital input defined to report first external fault is active. See parameter 3003 EXTERNAL FAULT 1.

-----

15 EXTERNAL FLT 2

Digital input defined to report second external fault is active. See parameter 3004 EXTERNAL FAULT 2.

-----

16 EARTH FAULT

Possible ground fault detected in the motor or motor cables. The drive monitors for ground faults while the drive is running and while the drive is not running. Detection is more sensitive when the drive is not running and can produce false positives.

Possible corrections:

• Check for/correct faults in the input wiring.

• Verify that motor cable does not exceed maximum specified length.

• A delta grounded input power supply and motor cables with high capacitance may result in erroneous error reports during non-running tests. To disable response to fault monitoring when the drive is not running, use parameter 3023 WIRING FAULT. To disable response to all ground fault monitoring, use parameter 3017 EARTH FAULT.

-----

17 UNDERLOAD

Motor load is lower than expected. Check for and correct:

• Disconnected load.

• Group 37: USER LOAD CURVE.

-----

18 THERM FAIL

Internal fault. The thermistor measuring the internal temperature of the drive is open or shorted. Contact your local ABB sales representative.

-----

19 OPEX LINK

Internal fault. A communication-related problem has been detected on the fiber optic link between the OITF and OINT boards. Contact your local ABB sales representative.

-----

20 OPEX PWR

Internal fault. Low voltage condition detected on OINT power supply.

Contact your local ABB sales representative.

-----

21 CURR MEAS

Internal fault. Current measurement is out of range. Contact your local ABB

sales representative.

-----

22 SUPPLY PHASE

Ripple voltage in the DC link is too high. Check for and correct:

• Missing mains phase.

• Blown fuse.

-----

23 ENCODER ERR

Not used (Available only with encoder and parameter Group 50).

-----

23 ENCODER ERR

The drive is not detecting a valid encoder signal. Check for and correct:

• Encoder presence and proper connection (reverse wired, loose connection, or short circuit).

• Voltage logic levels are outside of the specified range.

• A working and properly connected Pulse Encoder Interface Module, OTAC-01.

• Wrong value entered in parameter 5001 PULSE NR. A wrong value will only be detected if the error is such that the calculated slip is greater than 4 times the rated slip of the motor.

• Encoder is not being used, but parameter 5002 ENCODER ENABLE = 1 (ENABLED)

----- .

24 OVERSPEED

Motor speed is greater than 120% of the larger (in magnitude) of 2001 MINIMUM SPEED or 2002 MAXIMUM SPEED. Check for and correct:

• Parameter settings for 2001 and 2002.

• Adequacy of motor braking torque.

• Applicability of torque control.

• Brake chopper and resistor.

-----

25 RESERVED

Not used as of the publication of this manual.

-----

26 DRIVE ID

Internal fault. Configuration Block Drive ID is not valid. Contact your local ABB sales representative.

-----

27 CONFIG FILE

Internal configuration file has an error. Contact your local ABB sales representative.

-----

28 SERIAL 1 ERR

Fieldbus communication has timed out. Check for and correct:

• Fault setup (3018 COMM FAULT FUNC and 3019 COMM FAULT TIME).

• Communication settings (Group 51 or 53 as appropriate).

• Poor connections and/or noise on line.

-----

29 EFB CONFIG FILE

Error in reading the configuration file for the embedded fieldbus.

-----

30 FORCE TRIP

Fault trip forced by the fieldbus. See the fieldbus User’s Manual.

-----

31 EFB 1, 32 EFB 2 & 33 EFB 3

Fault code reserved for the embedded fieldbus (EFB) protocol application.

These codes are not used as of the publication of this manual.

-----

34 MOTOR PHASE

Fault in the motor circuit. One of the motor phases is lost. Check for and correct:

• Motor fault.

• Motor cable fault.

• Thermal relay fault (if used).

• Internal fault.

-----

35 OUTPUT WIRING

Possible power wiring error detected. When the drive is not running it monitors for an improper connection between the drive input power and the drive output. Check for and correct:

• Proper input wiring – line voltageis NOT connected to drive output.

• The fault can be erroneously declared if the input power is a delta grounded system and motor cable capacitance is large. This fault can be disabled using parameter 3023 WIRING FAULT.

-----

36 INCOMP SWTYPE

The drive cannot use the software.

• Internal Fault.

• The loaded software is not compatible with the drive.

• Call support representative.

-----

37 CB OVERTEMP

Drive control board is overheated.

Check for and correct:

• Excessive ambient temperatures

• Fan failure.

• Obstructions in the air flow.

-----

101 SERF CORRUPT,

-----

102 RESERVED,

-----

103 SERF MACRO,

-----

104 RESERVED, &105 RESERVED

Error internal to the drive. Contact your local ABB sales representative and report the error number.

-----

201 DSP T1 OVERLOAD,

-----

202 DSP T2 OVERLOAD,

-----

203 DSP T3 OVERLOAD,

-----

204 DSP STACK ERROR,

-----

205 RESERVED (obsolete),

-----

206 OMIO ID ERROR, & 207 EFB LOAD ERR

Error in the system. Contact your local ABB sales representative and report the error number.

-----

1000 PAR HZRPM LIMITS

Parameter values are inconsistent. Check for any of the following:

• 2001 MINIMUM SPEED > 2002 MAXIMUM SPEED.

• 2007 MINIMUM FREQ > 2008 MAXIMUM FREQ.

• 2001 MINIMUM SPEED / 9908 MOTOR NOM SPEED is outside proper range

(> 50)

• 2002 MAXIMUM SPEED / 9908 MOTOR NOM SPEED is outside proper range

(> 50)

• 2007 MINIMUM FREQ / 9907 MOTOR NOM FREQ is outside proper range

(> 50)

• 2008 MAXIMUM FREQ / 9907 MOTOR NOM FREQ is outside proper range

(> 50)

-----

1001 PAR PFAREFNG

Parameter values are inconsistent. Check for the following:

• 2007 MINIMUM FREQ is negative, when 8123 PFA ENABLE is active.

-----

1002 RESERVED (Obsolete)

-----

1003 PAR AI SCALE

Parameter values are inconsistent. Check for any of the following:

• 1301 AI 1 MIN > 1302 AI 1 MAX.

• 1304 AI 2 MIN > 1305 AI 2 MAX.

-----

1004 PAR AO SCALE

Parameter values are inconsistent. Check for any of the following:

• 1504 AO 1 MIN > 1505 AO 1 MAX.

• 1510 AO 2 MIN > 1511 AO 2 MAX.

-----

1005 PAR PCU 2

Parameter values for power control are inconsistent: Improper motor nominal kVA or motor nominal power. Check for the following:

• 1.1 < (9906 MOTOR NOM CURR * 9905 MOTOR NOM VOLT * 1.73 / PN) < 3.0

• Where: PN = 1000 * 9909 MOTOR NOM POWER (if units are kW)

or PN = 746 * 9909 MOTOR NOM POWER (if units are HP, e.g. in US)

-----

1006 EXT ROMISSING

Parameter values are inconsistent. Check for the following:

• Extension relay module not connected and

• 1410…1412 RELAY OUTPUTS 4…6 have non-zero values.

-----

1007 PAR FBUSMISSING

Parameter values are inconsistent. Check for and correct:

• A parameter is set for fieldbus control (e.g. 1001 EXT1 COMMANDS = 10 (COMM)), but 9802 COMM PROT SEL = 0.

-----

1008 PAR PFAWOSCALAR

Parameter values are inconsistent – 9904 MOTOR CTRL MODE must be = 3 (SCALAR: SPEED), when 8123 PFA ENABLE is activated.

-----

1009 PAR PCU1

Parameter values for power control are inconsistent: Improper motor nominal frequency or speed. Check for both of the following:

• 1 < (60 * 9907 MOTOR NOM FREQ / 9908 MOTOR NOM SPEED < 16

• 0.8 < 9908 MOTOR NOM SPEED /

(120 * 9907 MOTOR NOM FREQ / Motor Poles) < 0.992

-----

1010 PAR PFA OVERRIDE

Both the override mode and PFA are activated at the same time. These modes are mutually incompatible, because PFA interlocks cannot be observed in the override mode.

-----

1011 PAR OVERRIDE PARS

Override is enabled, but parameters are incompatible. Verify that 1701 is not zero, and (depending on 9904 value) 1702 or 1703 is not zero.

-----

1012 PAR PFA IO 1

IO configuration is not complete – not enough relays are parameterized to PFA. Or, a conflict exists between Group 14, parameter 8117, NR OF AUX MOT, and parameter 8118, AUTOCHNG INTERV.

-----

1013 PAR PFA IO 2

IO configuration is not complete – the actual number of PFA motors (parameter 8127, MOTORS) does not match the PFA motors in Group 14 and parameter 8118 AUTOCHNG INTERV.

-----

1014 PAR PFA IO 3

IO configuration is not complete – the drive is unable to allocate a digital input (interlock) for each PFA motor (parameters 8120 INTERLOCKS and 8127 MOTORS).

Alarm listing

The following table lists the alarms by code number and describes each.

2001 OVERCURRENT

Current limiting controller is active. Check for and correct:

• Excessive motor load.

• Insufficient acceleration time (parameters 2202 ACCELER TIME 1 and 2205 ACCELER TIME 2).

• Faulty motor, motor cables or connections.

-----

2002 OVERVOLTAGE

Over voltage controller is active. Check for and correct:

• Static or transient overvoltage in the input power supply.

• Insufficient deceleration time (parameters 2203 DECELER TIME 1 and 2206 DECELER TIME 2).

-----

2003 UNDERVOLTAGE

Under voltage controller is active. Check for and correct:

• Undervoltage on mains.

-----

2004 DIR LOCK

The change in direction being attempted is not allowed. Either:

• Do not attempt to change the direction of motor rotation, or

• Change parameter 1003 DIRECTION to allow direction change (if

reverse operation is safe).

-----

2005 I/O COMM

Fieldbus communication has timed out. Check for and correct:

• Fault setup (3018 COMM FAULT FUNC and 3019 COMM FAULT TIME).

• Communication settings (Group 51 or 53 as appropriate).

• Poor connections and/or noise on line.

-----

2006 AI1 LOSS

Analog input 1 is lost, or value is less than the minimum setting.

Check:

• Input source and connections

• Parameter that sets the minimum (3021)

• Parameter that sets the Alarm/Fault operation (3001)

-----

2007 AI2 LOSS

Analog input 2 is lost, or value is less than the minimum setting.

Check:

• Input source and connections

• Parameter that sets the minimum (3022)

• Parameter that sets the Alarm/Fault operation (3001)

-----

2008 PANEL LOSS

Panel communication is lost and either:

• Drive is in local control mode (the control panel displays HAND or OFF), or

• Drive is in remote control mode (AUTO) and is parameterized to accept start/stop, direction or reference from the control panel.

To correct check:

• Communication lines and connections

• Parameter 3002 PANEL LOSS.

• Parameters in Groups 10 START/STOP/DIR and 11: REFERENCE SELECT (if drive operation is AUTO).

-----

2009 DEVICE OVERTEMP

Drive heatsink is hot. This alarm warns that a DEVICE OVERTEMP fault may be near.

R1…R4 & R7/R8: 100 °C (212 °F)

R5/R6: 110 °C (230 °F)

Check for and correct:

• Fan failure.

• Obstructions in the air flow.

• Dirt or dust coating on the heat sink.

• Excessive ambient temperature.

• Excessive motor load.

-----

2010 MOT OVERTEMP

Motor is hot, based on either the drive’s estimate or on temperature feedback. This alarm warns that a Motor Underload fault trip may be near. Check:

• Check for overloaded motor.

• Adjust the parameters used for the estimate (3005…3009).

• Check the temperature sensors and Group 35 parameters.

-----

2011 UNDERLOAD

Motor load is lower than expected. This alarm warns that a Motor Underload fault trip may be near. Check:

• Motor and drive ratings match (motor is NOT undersized for the drive)

• Settings Group 37: USER LOAD CURVE

-----

2012 MOTOR STALL

Motor is operating in the stall region. This alarm warns that a Motor Stall fault trip may be near.

-----

2013 (note 1) AUTORESET

This alarm warns that the drive is about to perform an automatic fault reset, which may start the motor.

• To control automatic reset, use parameter Group 31: AUTOMATIC RESET.

-----

2014 (note 1) AUTOCHANGE

This alarm warns that the PFA autochange function is active.

• To control PFA, use parameter Group 81: PFA CONTROL

-----

2015 PFA INTERLOCK

This alarm warns that the PFA interlocks are active, which means that

the drive cannot start the following:

• Any motor (when Autochange is used),

• The speed regulated motor (when Autochange is not used).

-----

2016 Reserved

-----

2017 OFF BUTTON

Note 1.

-----

2018 (note 1) PID SLEEP

This alarm warns that the PID sleep function is active, which means that the motor could accelerate when the PID sleep function ends.

• To control PID sleep, use parameters 4022…4026 or 4122…4126.

-----

2019 ID RUN

Performing ID run.

-----

2020 OVERRIDE

This alarm warns that the Override function is active, which may start the motor.

-----

2021 START ENABLE 1 MISSING

This alarm warns that the Start Enable 1 signal is missing.

• To control Start Enable 1 function, use parameter 1608.

To correct, check:

• Digital input configuration.

• Communication settings.

-----

2022 START ENABLE 2 MISSING

This alarm warns that the Start Enable 2 signal is missing.

• To control Start Enable 2 function, use parameter 1609.

To correct, check:

• Digital input configuration.

• Communication settings.

-----

2023 EMERGENCY STOP

Emergency stop activated.

-----

2024 ENCODER ERROR

The drive is not detecting a valid encoder signal. Check for and correct:

• Encoder presence and proper connection (reverse wired, loose connection, or short circuit).

• Voltage logic levels are outside of the specified range.

• A working and properly connected Pulse Encoder Interface Module, OTAC-01.

• Wrong value entered in parameter 5001 PULSE NR. A wrong value will only be detected if the error is such that the calculated slip is greater than 4 times the rated slip of the motor.

• Encoder is not being used, but parameter 5002 ENCODER ENABLE =

1 (ENABLED).

-----

2025 FIRST START

Signals that a the drive is performing a First Start evaluation of motor characteristics. This is normal the first time the motor is run after motor parameters are entered or changed. See parameter 9910 (MOTOR ID RUN) for a description of motor models.

-----

2026 RESERVED

Not used.

-----

2027 USER LOAD CURVE

This alarm warns that the condition defined by parameter 3701 USER LOAD C MODE has been valid longer that half of the time difined by 3703 USER LOAD C TIME.

-----

2028 START DELAY

Shown during the Start delay. See parameter 2113 START DELAY.

-----

Note 1. Even when the relay output is configured to indicate alarm conditions (e.g. parameter 1401 RELAY OUTPUT 1 = 5 (ALARM) or 16 (FLT/ALARM)), this alarm is not indicated by a relay output.

If you determine that your ABB ACH550 drive is suspected of being the problem, or you are not sure, give us a call at 800-732-4695 and talk to one of our sales team. We have factory trained technicians for ABB drive products and we can get your defective unit running like new quickly and economically. We also repair, and are very familiar with, ACH550 bypass products.

For additional troubleshooting information, click the link below to upload the Diagnostics Section of the ABB ACH550 series user manual.

ACH550 Diagnostics User Manual

Back To Blog

ABB ACH550 FAULT CODES ALARMS ACH550-UH-024A-2

ABB ACH550 FAULT CODES ALARMS ACH550-UH-024A-2