1.Warranty time: 1 year

2.Delivery time: 3-5 days

3.Product quality: new or discontinued second-hand

1. We are a global trading company, we have a large stock of spare parts, we also produce energy storage batteries

2. Our main sales products are industrial automation control equipment accessories, such as: controller board, processor module, communication module, input and output module, power module (various circuit boards and cards), touch screen, servo driver, servo motor, sensor, cable......

3. We can not only provide new products, but also supply cold and discontinued spare parts, all the discontinued parts will go through strict testing to ensure the reliability of product performance, so that customers can buy and use at ease

4. For more information, please contact us: Contact: Amy | Email: saul01@qq.com | Tel(WhatsApp/Wechat): +86-15359298283

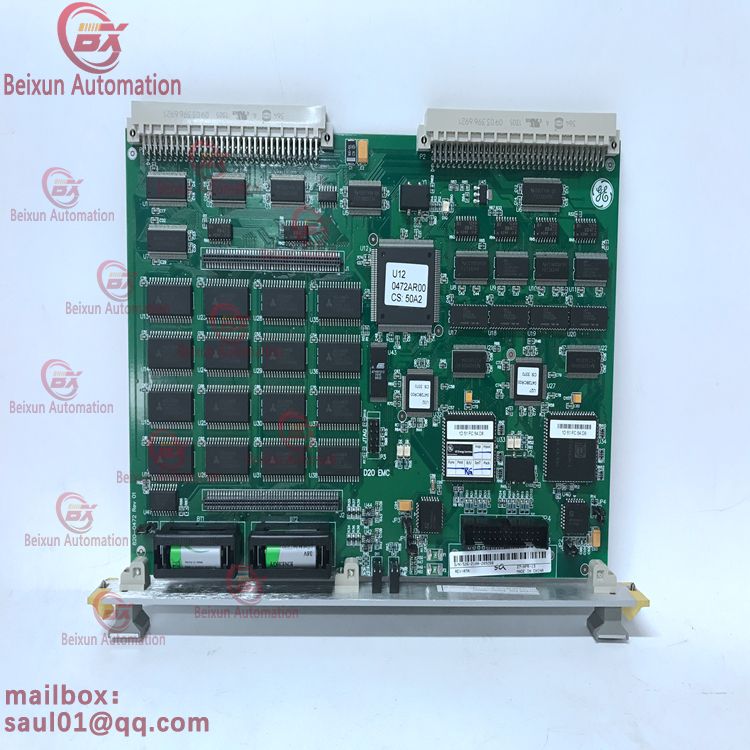

GE D20 EME drive

GE D20 EME drive

GE D20 EME drive

The D20 EME drive is ideal for machines with a low number of axes. This new driver offers output power as low as 50 W, allowing you to customize the number of shafts in your machine according to actual power requirements, which minimizes system size and reduces costs. Due to their small size and low power range, these drives have a wide range of applications, including:

• Intermittent forming, filling and sealing

• Index positioning workbench

• Laboratory automation equipment

• Medical technology and manufacturing

• Solar panel tracking

• Light industrial manufacturing

• Electronic assembly

• Semiconductor processing

Core control unit components

Core control unit components (CCBB) provide additional ease of use when applying D20EME component servo drives to a Core control unit solution. CCBB provides CAD drawings, electrical design drawings, bills of materials, sample codes, and developed operator images. CCBB component not only has the function of parameter backup and parameter recovery, but also has the function of diagnosis. CCBB can help simplify the application of servo solutions.

The components of the D20 EME include the MicroLogix 1400 controller, the PVC operator interface and the TL series motor, which enables the function of index positioning control for up to three axes via Modbus-RTU.

Product technical parameters

1. Continuous power output depends on the connected motor. In most cases, the drive can continuously deliver more power than listed under rated speed conditions by slightly reducing torque. Application estimates can be verified using a motion analyzer.

2. In this case, the Bulletin TLY series motor must be used until the equivalent Bulletin TL motor is available.

Communication and control modes

Modbus-RTU

• Advanced diagnostics and controls, including index positioning and preset speed command modes

• Two serial port sockets to make wiring easier when forming a Daisy chain

• Sample code can be used

User I/O control

• Simple and economical

• No upper servo pulse module required

• Sensors can be used directly to trigger index positioning or preset speeds

• Support analog control and pulse train control

GE D20 EME drive